The Söhnergroup becomes iwis mechatronics

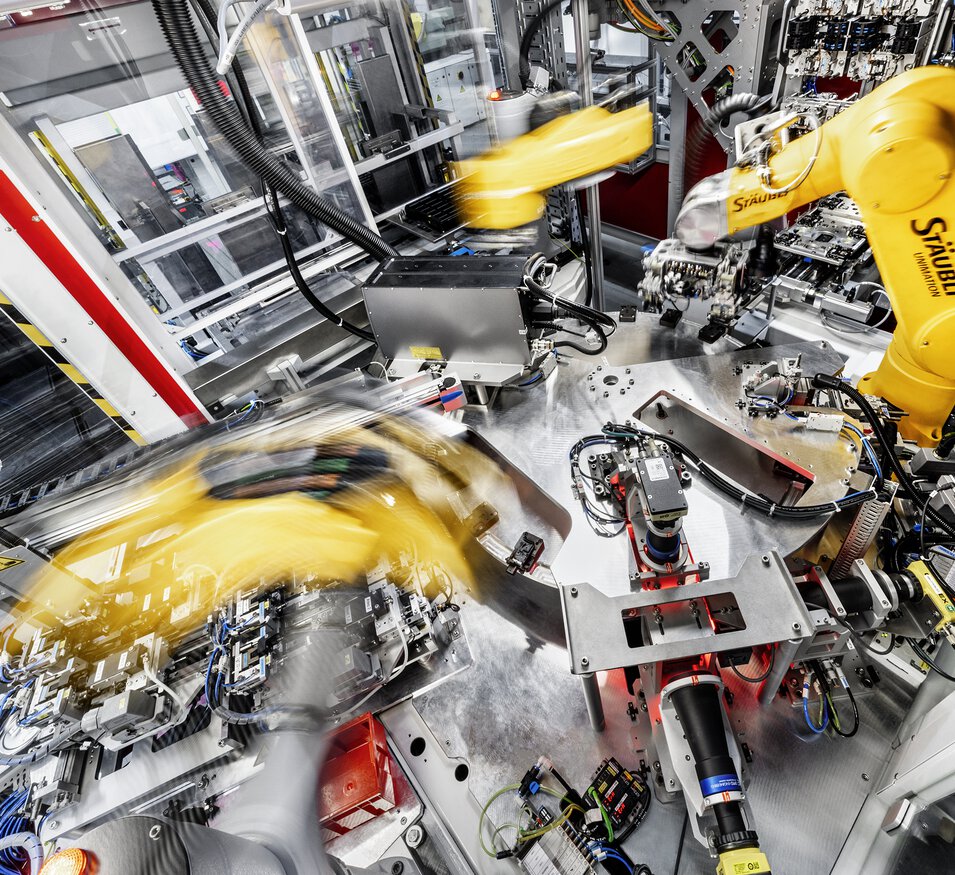

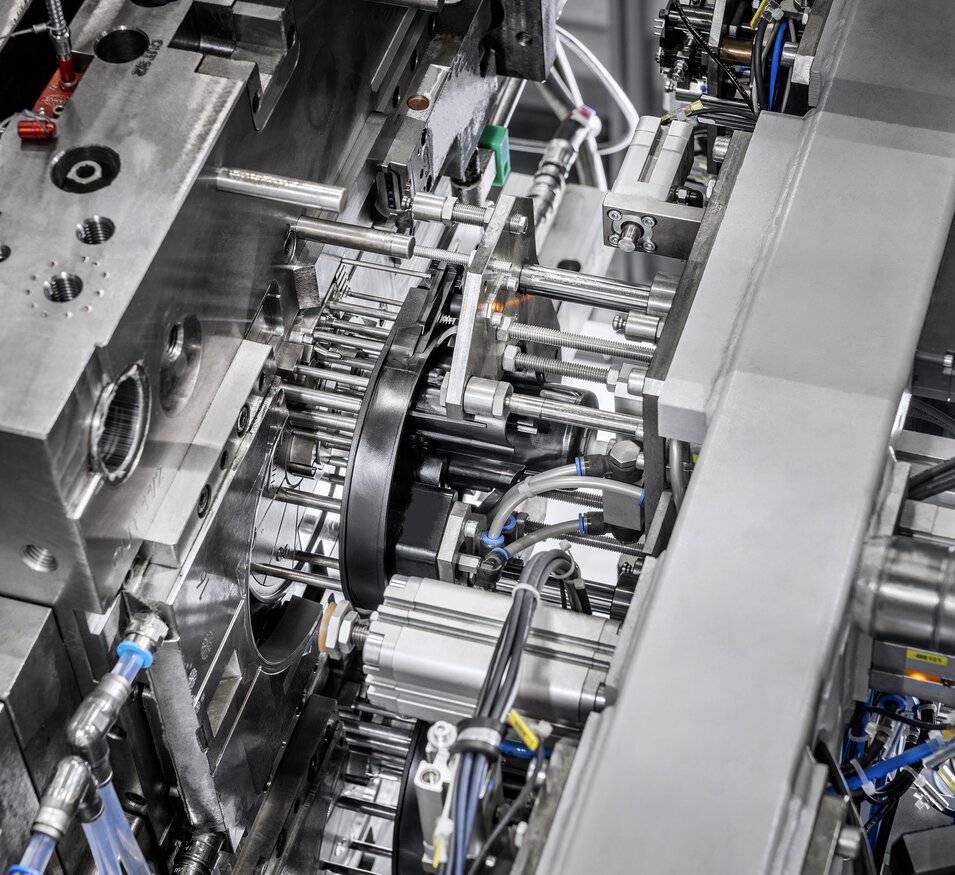

Engineering, Products, Processes and Technologies - with iwis mechatronics as a Solution Partner, there is an intelligent solution for everything.

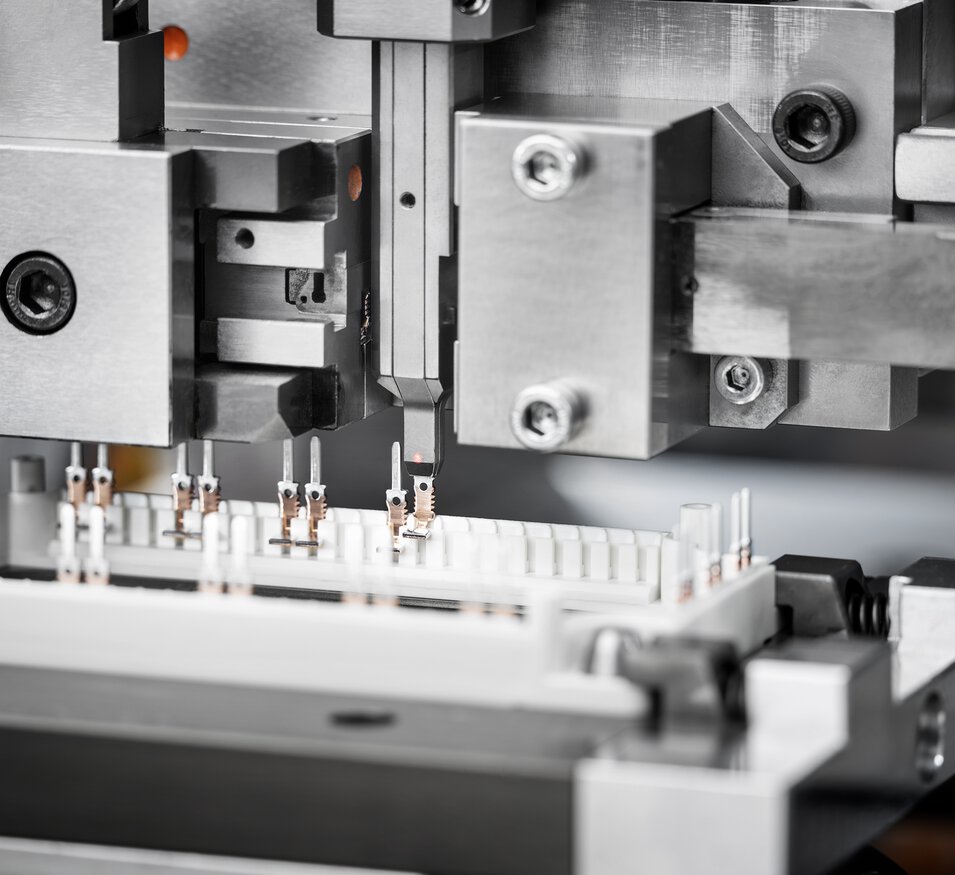

We are a specialist for high-precision plastic-metal components and modules and a leading production and development partner for automotive as well as non-automotive applications. In addition to battery contact systems for electric vehicles, iwis mechatronics also develops products for the renewable energy, medical technology and consumer goods sectors, among others.